No news to report with the exception that later this summer I will most likely have another one of these lathes in my possession. Once the deal is done will advise you about it. As well Last summer a lady contacted me about a Hardinge Cataract Toolroom(QC) lathe they had. This person was from somewhere around the Flagstaff Arizona area. She contacted me after seeing my posts online in one of the Metal Forums I monitor, or after reading this Blog, ref restoring one of these Lathes. Unfortunately I have lost her email. Ma'am if you perchance read this thread could you please email or contact me via this Blog. Thanks very much.

On a personal note. I have about one month left in the current house before I take up residence with my Mom until my new house is built. I'm still hoping to start this endeavour in early September.

Well all the best for the rest of the summer.

Also Go Holland Go. Maybe this year she'll win the World Cup.

Harold

This will follow the project of restoring 1917 Hardinge Cataract Lathe back to working condition. As well any tooling needed will be discussed as well

Friday, 27 June 2014

Sunday, 8 June 2014

Just a short little update. I've moved three loads of truck and trailer down to the new location in Niagara on the lake. This past weekend I went down with only the truck since I had long stuff that required the tailgate to be down for the trip. My garage is pretty empty and the house is getting bare as well. I've packed a lot of stuff already and all the pictures that were on the wall have been moved to my Mom's place. Moved all the scotch too this past weekend. I thought I would pass on a few pictures. The first one will be of the lot I have purchased and am awaiting possession. The trees on the left are on my property and will taken down by the seller.

As well after numerous iterations the following few pictures will give you a general view of what the house and garage will look like on the lot. The pictures unfortunately are not the best due to the way the cheap drafting program exports the image.

The garage will be 24ft deep by 32ft wide. The house will be 34ft wide by 54ft deep and then there will be a 6ft porch on the front and a 10ft porch on the rear. The way the house is built the deck surface will be 16ft by 17ft on the south east corner of the house. This will provide a nice area for table and chairs.

Well a couple of more trips back and forth and then the Movers will take all the big stuff a month from now.

Well to all enjoy the warm weather and have a great summer

Harold

As well after numerous iterations the following few pictures will give you a general view of what the house and garage will look like on the lot. The pictures unfortunately are not the best due to the way the cheap drafting program exports the image.

The garage will be 24ft deep by 32ft wide. The house will be 34ft wide by 54ft deep and then there will be a 6ft porch on the front and a 10ft porch on the rear. The way the house is built the deck surface will be 16ft by 17ft on the south east corner of the house. This will provide a nice area for table and chairs.

Well a couple of more trips back and forth and then the Movers will take all the big stuff a month from now.

Well to all enjoy the warm weather and have a great summer

Harold

Saturday, 10 May 2014

Just a short update. If all goes well on Monday will be putting in an offer on Lot in Virgil Ontario. Lot is 63ftwide by 200ft long and has all city services at the lot line. This will allow me to build a nice house with a decent sized garage. Only real issue is that I most likely will not get possession of the lot until Mid August which means I will not be in the house until late this year. This means not much more restoration news until very late this year or early next year once the garage is usable.

This weekend will be taking the first of at least three loads by truck and trailer down to the Virgil area. I planned on moving all my tooling and the things the movers will not take and let them do the rest of the house. So yesterday I loaded up the #86 lathe into the back of the pickup truck and this morning I loaded the Van Norman #10 mill and a snowblower. Here are a couple of pictures showing the load.

Tomorrow morning at the crack of dawn we'll be off down the 401 to St Catharines to drop all this stuff off in my Mom's garage. Unfortunately I the storage facility that I want to use in Virgil is full up and will not have a unit available until end May. This means my next load will be beginning of June hopefully straight into the storage facility. This load will stay in my Mom's garage until either the house is ready or I need to move it due winter approaching.

One thing to relate on the restoration front. It's amazing the things you find out when you take things apart especially if you have two of the same machines to compare to each other. When I restored the #39 the crossfeed nut which is a Bronze alloy was secured to the crossfeed assembly by a plain old bolt. When I was disassembling the carriage for moving I noticed that there was a screw in the bolt on this carriage. I initially thought this might be a locking screw assembly however upon removal and clearing the bolt head. I noticed the word "Oil" on the bolt head. After removal I noticed a hole completely through the bolt to allow oil to be inserted to oil the crossfeed thread. So evidently on the #39 either somebody lost this nut or damaged it and replaced it with a plain old bolt. I guess when I am up and running will need to make a bolt similar to the one from the #86 for the #39.

Well all the best and enjoy the coming months. The weather is finally starting to get warm here such that the neighbourhood kids were even playing with soaker guns yesterday. Hurray for warm weather.

Harold

This weekend will be taking the first of at least three loads by truck and trailer down to the Virgil area. I planned on moving all my tooling and the things the movers will not take and let them do the rest of the house. So yesterday I loaded up the #86 lathe into the back of the pickup truck and this morning I loaded the Van Norman #10 mill and a snowblower. Here are a couple of pictures showing the load.

Tomorrow morning at the crack of dawn we'll be off down the 401 to St Catharines to drop all this stuff off in my Mom's garage. Unfortunately I the storage facility that I want to use in Virgil is full up and will not have a unit available until end May. This means my next load will be beginning of June hopefully straight into the storage facility. This load will stay in my Mom's garage until either the house is ready or I need to move it due winter approaching.

One thing to relate on the restoration front. It's amazing the things you find out when you take things apart especially if you have two of the same machines to compare to each other. When I restored the #39 the crossfeed nut which is a Bronze alloy was secured to the crossfeed assembly by a plain old bolt. When I was disassembling the carriage for moving I noticed that there was a screw in the bolt on this carriage. I initially thought this might be a locking screw assembly however upon removal and clearing the bolt head. I noticed the word "Oil" on the bolt head. After removal I noticed a hole completely through the bolt to allow oil to be inserted to oil the crossfeed thread. So evidently on the #39 either somebody lost this nut or damaged it and replaced it with a plain old bolt. I guess when I am up and running will need to make a bolt similar to the one from the #86 for the #39.

Well all the best and enjoy the coming months. The weather is finally starting to get warm here such that the neighbourhood kids were even playing with soaker guns yesterday. Hurray for warm weather.

Harold

Saturday, 26 April 2014

Well I hope you all had a nice Easter. I also hope that spring and summer come soon. This cold weather we're having is starting to become depressing. However there are at least two good things that have happened lately. The first is that my house has officially sold and I will be moving to St Catharines/Niagara-on-the-lake later this summer. Because of this I will be essentially putting my blog on hold until I am up and running in the new house. This edition will be the last big writeup for restoration purposes. I may put up some small updates as the summer goes, but this will most likely be the last restoration work related blog until my guess the end of summer. So for those who look me up I wish you all the best for the summer and look forward to seeing you come back in late summer early fall for more updates.

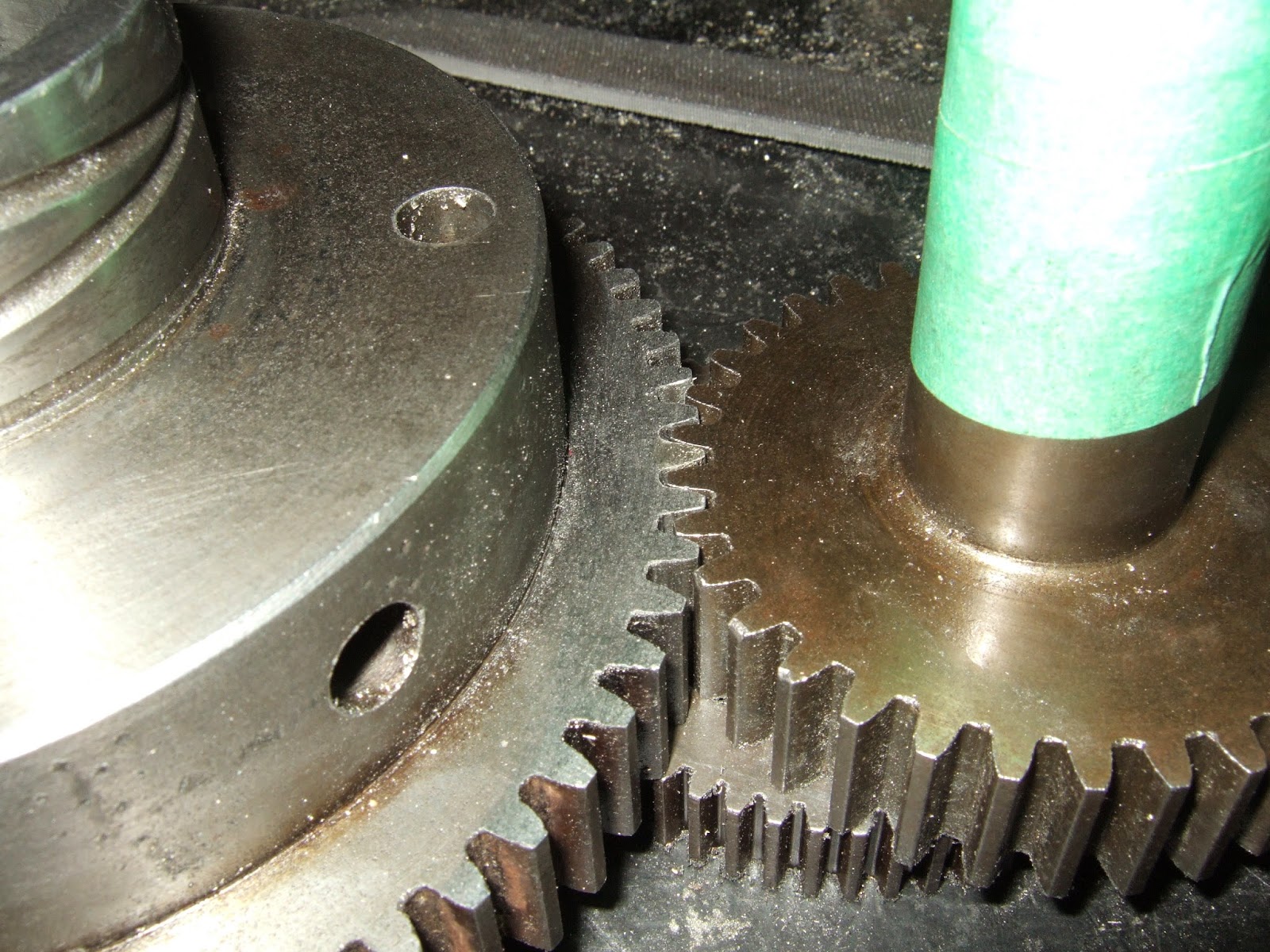

The other good news is that as of now we have success on repairing the broken teeth on the Bull and Back gear. As you recall when I left you two weeks ago I had brazed one tooth on the back gear and was getting ready to weld up the second gear. Well the second gear was brazed up and once cool both welds were cleaned up and filed down to tooth height. Here are two pictures showing the braxing on opposite sides of the gear and one side filed down to height.

Now it was over to the milling machine to use the involute gear cutters I bought to cut out the tooth profile. Prior to doing this I roughed out some slots for the space between teeth so as to minimize the amount of material the cutter needed to remove. I snugged up the gear in the vice and then using a square ensured the groove was vertical to the milling table by lining up the groove with the centre of the shaft and then rotating the gear until the centre of the groove lined up with the square. This took a little time but worked out pretty good. I then moved the table in so the cutter centre was lined up with the centre of the groove. As the cutting operation was carried out I slightly adjusted this "Y" axis to ensure proper tooth placement. After have a dozen passes going no more than 15thous at a time the first groove was done. Then rotate the gear and do the process all over again. After 4 setups both gear teeth were cut out. Checked them with the Bull gear and they work pretty good. I will need to clean them up slightly with some filing however for now the Back gear is replaced. Here are some pictures showing the various setups and the results of the milling process.

After this proved to be successful I carefully brazed up the Bull gear by the same process. Drilled and tapped for 2 #10-24 set screws and then heated up the part. Brazed in the repair and placed in the kitty litter for cool down. Once part was cooled removed and cleaned up the brazing as well as cut some grooves to remove material prior to machining. Once this was done over to the mill and same as before centred up the part using square and cut first groove. Once this was done repeat for second cut. On the Bull gear only one tooth was broken and missing so after two operations we were done with the Bull gear. Then it was over to the bench to finish file the tooth down. One of the reasons for filing is that although this is the correct cutter there was an ever so slight difference in the profile of the cutter and the original teeth. The cutter left a more rounded bottom were as the original tooth profile had a squarer bottom as well I needed to then the tooth slightly. The cutter seemed to be slightly thinner than the groove in the original teeth. Oh well nothing that 20 min at the table filing couldn't fix. Here are some pictures of work on the Bull gear and the final shot showing the meshing of the teeth from Bull to Back gear.

The last thing I've done is clean up the Back gear and then prime and paint the rough cast iron surface. Here is a final pictures showing the back gear prepped and primed.

Well as mentioned above this will be the last installment of the restoration Project until I get setup in my new house. Over the next few weeks I will be going to the new location to find a house and then I plan on moving the machinery myself during the Month of May by doing weekly trips to visit Mom and dropping of stuff into storage. I will most likely just post small updates on how everything is going but no major write ups till late summer or early fall. Until then have a great summer and don't get to sunburned.

Harold

The other good news is that as of now we have success on repairing the broken teeth on the Bull and Back gear. As you recall when I left you two weeks ago I had brazed one tooth on the back gear and was getting ready to weld up the second gear. Well the second gear was brazed up and once cool both welds were cleaned up and filed down to tooth height. Here are two pictures showing the braxing on opposite sides of the gear and one side filed down to height.

Now it was over to the milling machine to use the involute gear cutters I bought to cut out the tooth profile. Prior to doing this I roughed out some slots for the space between teeth so as to minimize the amount of material the cutter needed to remove. I snugged up the gear in the vice and then using a square ensured the groove was vertical to the milling table by lining up the groove with the centre of the shaft and then rotating the gear until the centre of the groove lined up with the square. This took a little time but worked out pretty good. I then moved the table in so the cutter centre was lined up with the centre of the groove. As the cutting operation was carried out I slightly adjusted this "Y" axis to ensure proper tooth placement. After have a dozen passes going no more than 15thous at a time the first groove was done. Then rotate the gear and do the process all over again. After 4 setups both gear teeth were cut out. Checked them with the Bull gear and they work pretty good. I will need to clean them up slightly with some filing however for now the Back gear is replaced. Here are some pictures showing the various setups and the results of the milling process.

The last thing I've done is clean up the Back gear and then prime and paint the rough cast iron surface. Here is a final pictures showing the back gear prepped and primed.

Well as mentioned above this will be the last installment of the restoration Project until I get setup in my new house. Over the next few weeks I will be going to the new location to find a house and then I plan on moving the machinery myself during the Month of May by doing weekly trips to visit Mom and dropping of stuff into storage. I will most likely just post small updates on how everything is going but no major write ups till late summer or early fall. Until then have a great summer and don't get to sunburned.

Harold

Subscribe to:

Posts (Atom)