The other good news is that as of now we have success on repairing the broken teeth on the Bull and Back gear. As you recall when I left you two weeks ago I had brazed one tooth on the back gear and was getting ready to weld up the second gear. Well the second gear was brazed up and once cool both welds were cleaned up and filed down to tooth height. Here are two pictures showing the braxing on opposite sides of the gear and one side filed down to height.

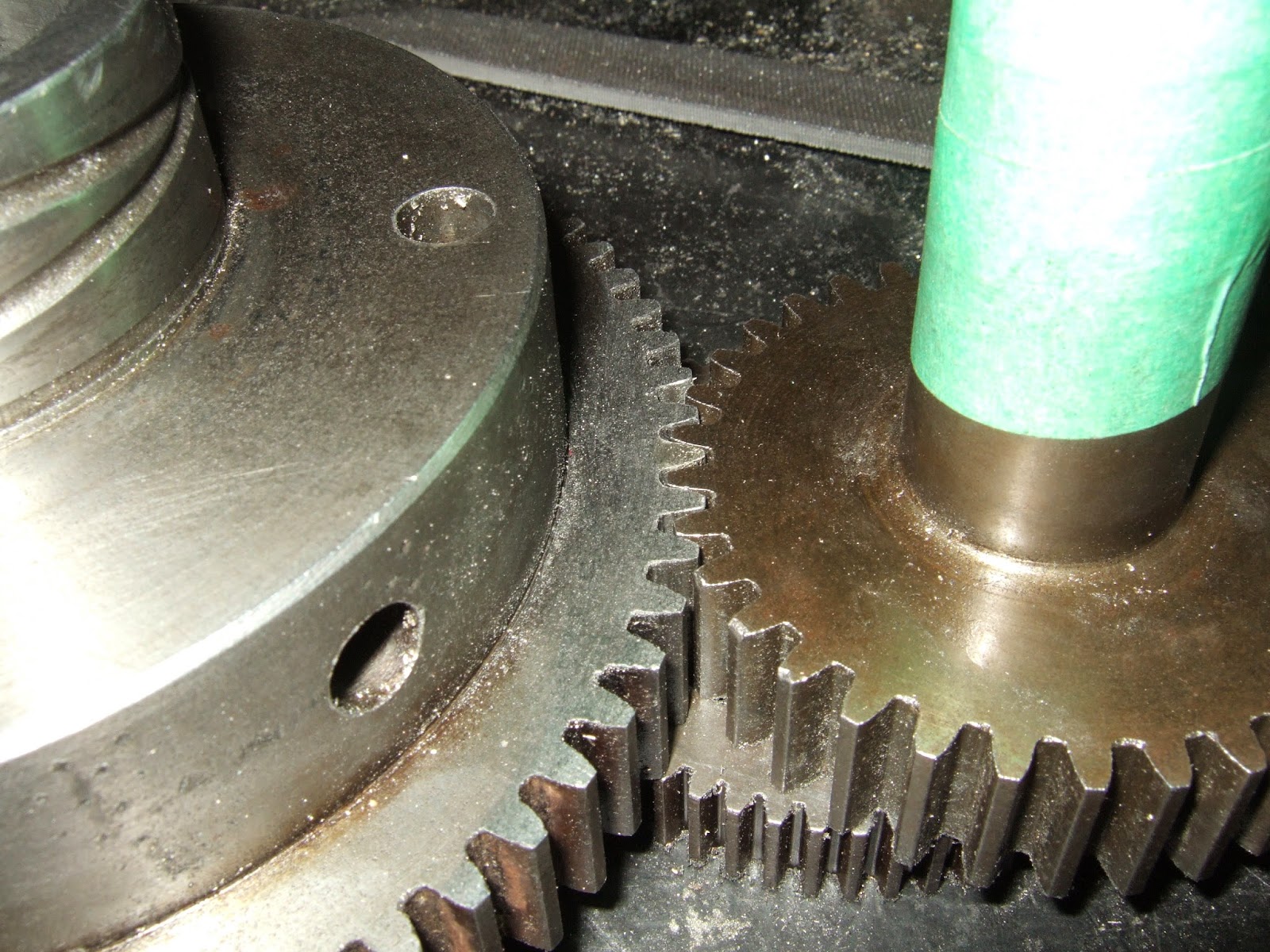

Now it was over to the milling machine to use the involute gear cutters I bought to cut out the tooth profile. Prior to doing this I roughed out some slots for the space between teeth so as to minimize the amount of material the cutter needed to remove. I snugged up the gear in the vice and then using a square ensured the groove was vertical to the milling table by lining up the groove with the centre of the shaft and then rotating the gear until the centre of the groove lined up with the square. This took a little time but worked out pretty good. I then moved the table in so the cutter centre was lined up with the centre of the groove. As the cutting operation was carried out I slightly adjusted this "Y" axis to ensure proper tooth placement. After have a dozen passes going no more than 15thous at a time the first groove was done. Then rotate the gear and do the process all over again. After 4 setups both gear teeth were cut out. Checked them with the Bull gear and they work pretty good. I will need to clean them up slightly with some filing however for now the Back gear is replaced. Here are some pictures showing the various setups and the results of the milling process.

The last thing I've done is clean up the Back gear and then prime and paint the rough cast iron surface. Here is a final pictures showing the back gear prepped and primed.

Well as mentioned above this will be the last installment of the restoration Project until I get setup in my new house. Over the next few weeks I will be going to the new location to find a house and then I plan on moving the machinery myself during the Month of May by doing weekly trips to visit Mom and dropping of stuff into storage. I will most likely just post small updates on how everything is going but no major write ups till late summer or early fall. Until then have a great summer and don't get to sunburned.

Harold

No comments:

Post a Comment